Understanding the Chemical Composition and Alloying Elements in Steel Production

Steel is an essential material in modern construction and manufacturing, and its properties are highly dependent on its chemical composition. The main components of steel are iron (Fe), carbon (C), and manganese (Mn). These elements, in various combinations, form the basis of different grades of steel that are used for specific applications. Additionally, other alloying elements are often added to enhance specific properties.

- Iron (Fe): Iron is the primary component of steel and forms the matrix in which other elements are embedded. It provides the basic structure and strength to the material.

- Carbon (C): Carbon is the principal hardening element in steel. It plays a crucial role in increasing the hardness and strength of steel. However, higher carbon concentrations can lead to certain issues, such as non-uniformity during casting and reduced ductility, toughness, and weldability. To address these concerns, newer grades of steel (HPS grades) have been developed with significantly lower carbon levels.

- Manganese (Mn): Manganese is another element that contributes to the hardening of steel, although its impact is less significant than carbon. Manganese can react with sulfur to form manganese sulfides, which may have adverse effects on material toughness and fatigue resistance.

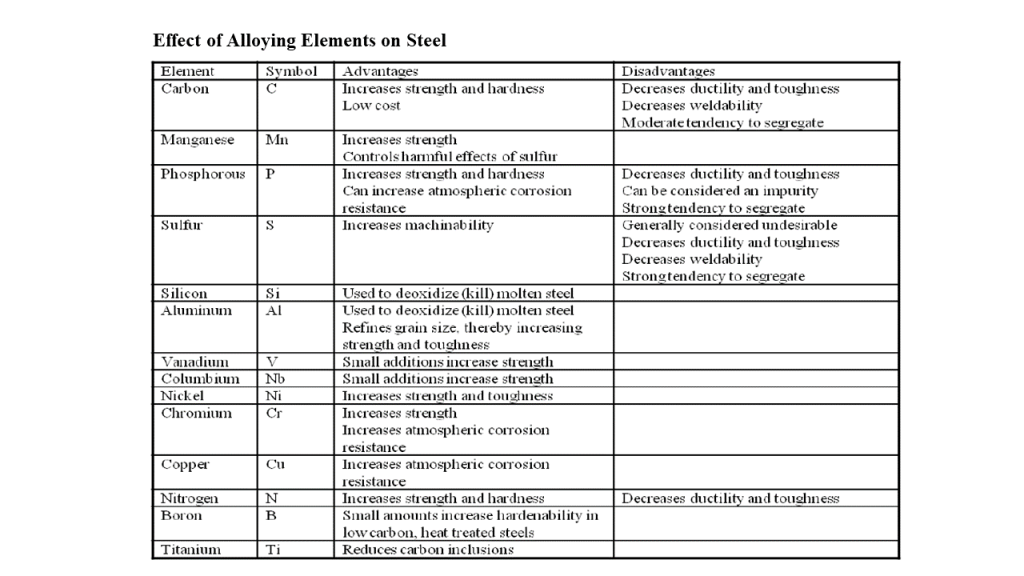

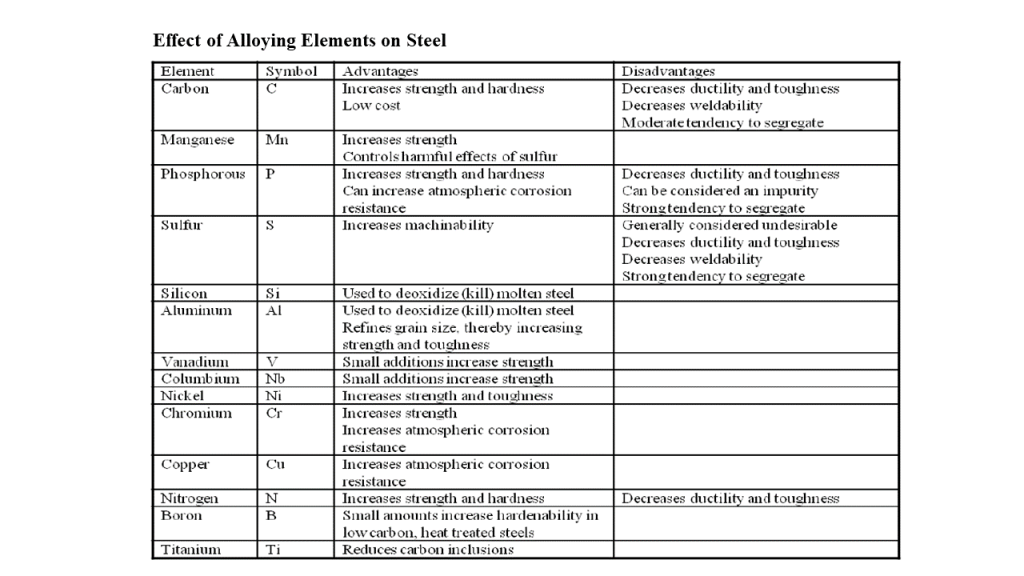

- Alloying Elements: Various alloying elements are added to steel to enhance specific properties. For example, alloying elements like chromium, nickel, molybdenum, and vanadium are commonly added to improve corrosion resistance, strength, and toughness. These alloying elements need to be carefully controlled within allowable limits to achieve the desired properties in the steel.

- Deoxidizing Elements: Aluminum and silicon are the primary deoxidizing elements used in the traditional manufacturing of carbon and alloy structural steels. Deoxidization is an important process in steel production that helps remove oxygen from the molten metal and prevents the formation of undesirable oxides that could weaken the material.

- Quality Control: Steel production involves tight control over the chemical composition to achieve the required properties. Steel specifications, such as ASTM A709 and others, provide tables indicating the allowable range of elemental composition for each grade of steel. These limits may be expressed as minimums, maximums, or a range, depending on the specific effects of the individual elements.

The chemical composition of steel is crucial in determining its mechanical properties, and alloying elements are added to achieve desired characteristics. Proper control and understanding of the interactions between these elements are essential to produce steel with the required strength, toughness, ductility, and other properties for various applications.

สำหรับช่องทางการประชาสัมพันธ์กิจกรรมต่าง ๆ และข้อมูลข่าวสาร ความรู้ ในรูปแบบอื่น ๆ ที่เกี่ยวข้องกับ เหล็กเพื่องานก่อสร้าง ของทางบริษัทฯ ยังมี Facebook Page และ Youtube Channel และ Line Officail Account ชื่อ “WeLoveSteelConstruction” นอกจากนี้ทาง บริษัทฯ ยังมีงานสัมมนาประจำปีที่มีเนื้อหาการบรรยายดี ๆ เกี่ยวข้องกับงานก่อสร้างด้วยเหล็ก รายละเอียดสามารถคลิกตามลิ้งค์ข้างล่างได้เลยครับ

#WeLoveSteelConstruction_Facebook