Residual Stresses in Steel Products and Their Impact on Fabrication for Bridge Design

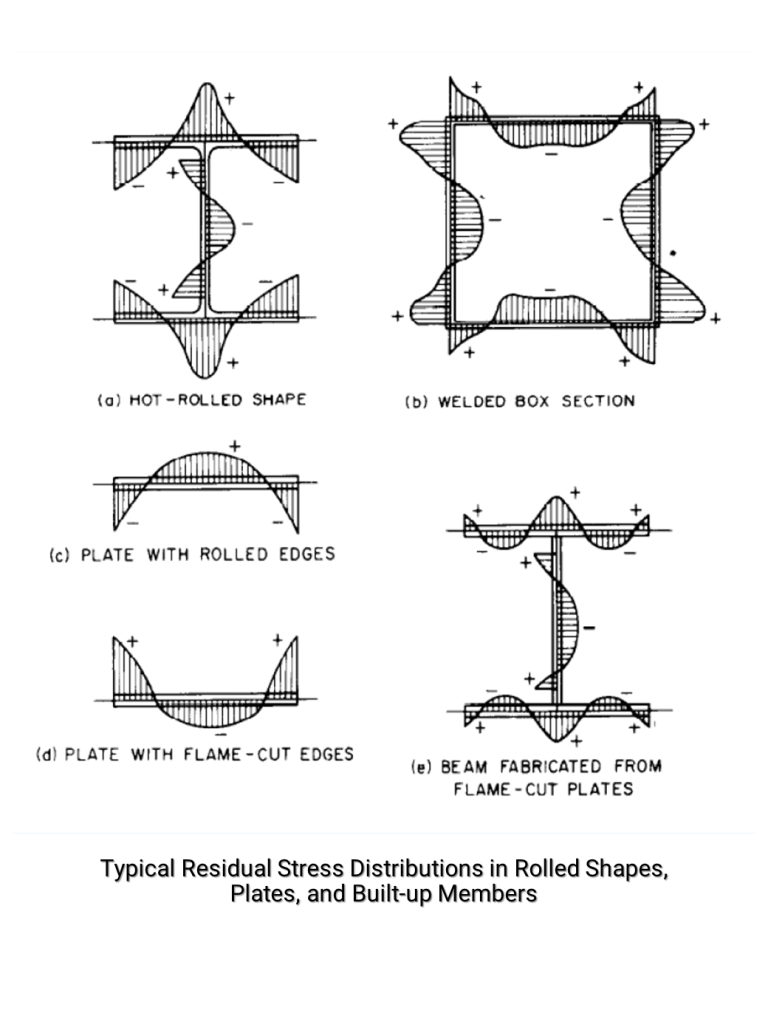

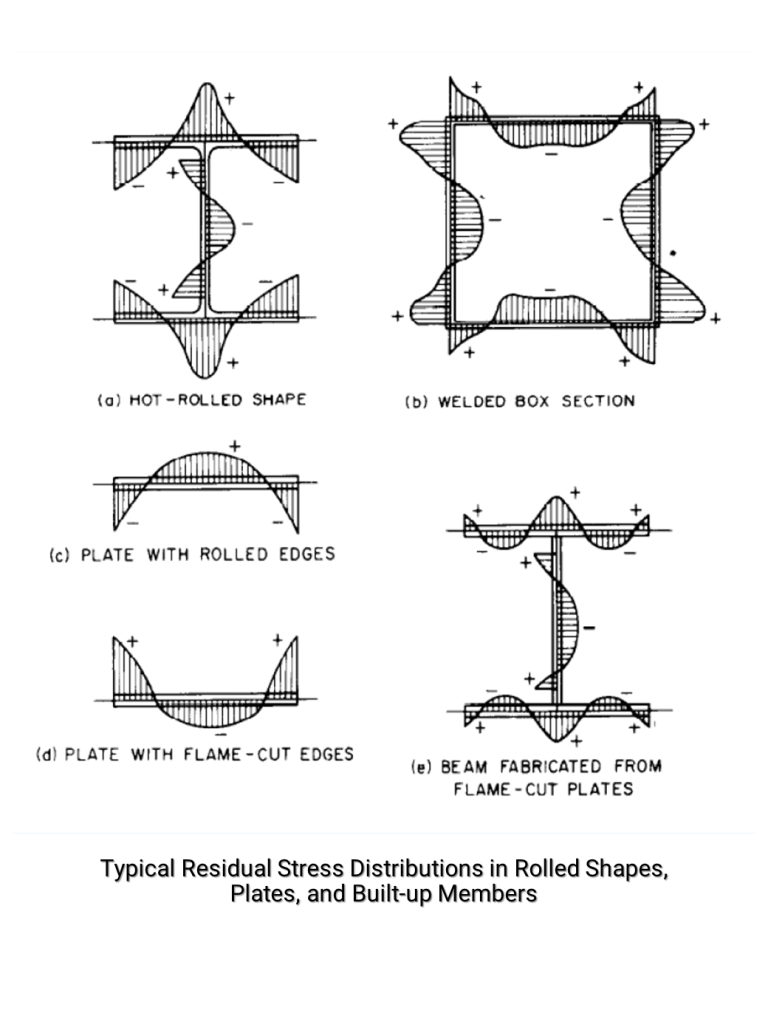

Residual stresses are an inherent characteristic of steel products resulting from the plastic deformation and differential cooling effects during their production processes. These stresses consist of both tensile (+) and compressive (-) components that remain in static equilibrium. Understanding the distribution and magnitude of residual stresses is crucial, as they can significantly influence the distortion and shape of fabricated steel members, ultimately affecting the performance and safety of structures like bridges.

- Causes: Residual stresses are generated during the manufacturing of steel products, particularly during rolling processes. Plastic deformation occurs when the steel undergoes shaping or forming operations, while differential cooling causes uneven temperature gradients within the material. These combined effects lead to the development of residual stresses within the steel.

- Types: Residual stresses in steel products can have both tensile (+) and compressive (-) components. The presence of these stresses can be attributed to the uneven distribution of strain and temperature changes experienced during production. The resulting stress distribution can be non-uniform and vary based on the shape geometry and processing techniques used.

- Impact on Fabrication: Fabrication operations, such as welding, flame cutting, and hole drilling, can alter the residual stress pattern in steel members. This alteration can lead to distortion in the form of plate flatness, twist, and straightness. Experienced fabricators have learned to compensate for these distortional changes to ensure that the final fabricated steel members meet the required dimensional tolerances.

- Measuring: Determining the exact distribution and magnitude of residual stresses in fabricated members is a challenging process that often requires destructive techniques like sectioning and hole drilling. Non-destructive methods, such as X-ray diffraction and neutron diffraction, are also available but are generally more suitable for research purposes due to their impracticality in routine applications.

- Importance in Bridge Design: From a designer’s perspective, understanding residual stresses is not always necessary when calculating the strength of bridge members. Standards like the AASHTO LRFD BDS already account for residual stresses in their buckling equations for flexural and compression members. They are also considered in fatigue resistance data used to establish S-N curves.

- Localized Issues and Details: While designers may not always require knowledge of residual stresses for overall bridge member strength calculations, there are situations where localized issues and details necessitate this information. In such cases, consultation with experienced fabricators and specialized techniques can provide the necessary data for evaluations.

Residual stresses in steel products are an essential consideration in the fabrication and design of structures, especially in critical applications like bridges. Understanding their distribution and impact on fabrication helps ensure the final products meet the required tolerances and perform optimally. By collaborating with experienced fabricators and utilizing appropriate techniques, engineers can address localized issues effectively and design safer and more resilient steel structures.

สำหรับช่องทางการประชาสัมพันธ์กิจกรรมต่าง ๆ และข้อมูลข่าวสาร ความรู้ ในรูปแบบอื่น ๆ ที่เกี่ยวข้องกับ เหล็กเพื่องานก่อสร้าง ของทางบริษัทฯ ยังมี Facebook Page และ Youtube Channel และ Line Officail Account ชื่อ “WeLoveSteelConstruction” นอกจากนี้ทาง บริษัทฯ ยังมีงานสัมมนาประจำปีที่มีเนื้อหาการบรรยายดี ๆ เกี่ยวข้องกับงานก่อสร้างด้วยเหล็ก รายละเอียดสามารถคลิกตามลิ้งค์ข้างล่างได้เลยครับ

#WeLoveSteelConstruction_Facebook