“Weathering Steel” The Art of Rust and Corrosion Resistance

Weathering steel, also known as COR-TEN steel, is a type of high-strength, low-alloy steel that contains certain alloying elements, primarily copper, chromium, nickel, and phosphorus. The most common grade of weathering steel is ASTM A588, but there are other grades as well.

It is renowned for its unique ability to develop a protective patina over time when exposed to the elements. This patina forms due to the interaction between the steel and the environment, particularly in outdoor conditions with exposure to moisture, oxygen, and pollutants. The patina acts as a protective barrier, slowing down the corrosion rate of the steel and enhancing its resistance to atmospheric corrosion compared to regular carbon steel.

History and Developmen

COR-TEN steel was first developed in the 1930s by the United States Steel Corporation. The aim was to create a steel alloy that would resist corrosion while maintaining its structural integrity without the need for paint or coatings. The name “COR-TEN” is a contraction of the words “corrosion resistance” and “tensile strength,” which aptly describes the steel’s primary attributes.

Composition and Properties

The key elements that differentiate weathering steel from traditional carbon steel are copper, chromium, nickel, and phosphorus. These alloying elements promote the formation of a stable patina on the steel’s surface, providing protection against corrosion caused by atmospheric elements like rain, humidity, and pollutants. As the steel is exposed to the environment over time, the patina evolves, creating a stunning orange-brown appearance that blends harmoniously with nature.

Advantages

Corrosion Resistance: The most significant advantage of weathering steel is its exceptional resistance to atmospheric corrosion. The protective patina prevents the penetration of moisture and corrosive agents, significantly extending the material’s lifespan.

Aesthetic Appeal: The distinctive rusty appearance of weathering steel adds a unique and captivating aesthetic to any project. Its natural, earthy hues complement both modern and traditional architecture, making it a popular choice for artistic sculptures, building facades, and landscaping.

Low Maintenance: Weathering steel requires little to no maintenance, unlike traditional carbon steel that necessitates regular painting and protective coatings. This attribute reduces ongoing costs and makes it an eco-friendly option.

High Strength: Despite its rustic appearance, weathering steel boasts high tensile strength, making it suitable for various structural applications, including bridges, outdoor sculptures, and large architectural projects.

Environmental advantages: Weathering steel is considered a “green” material as it reduces the need for ongoing maintenance, painting, and coatings, leading to a lower life-cycle cost and a smaller environmental footprint.

Applications

Architectural Structures: Weathering steel has become a favored choice for architects and designers in creating eye-catching building facades, roofing, and decorative elements. Its unique appearance adds character and blends harmoniously with both urban and natural landscapes.

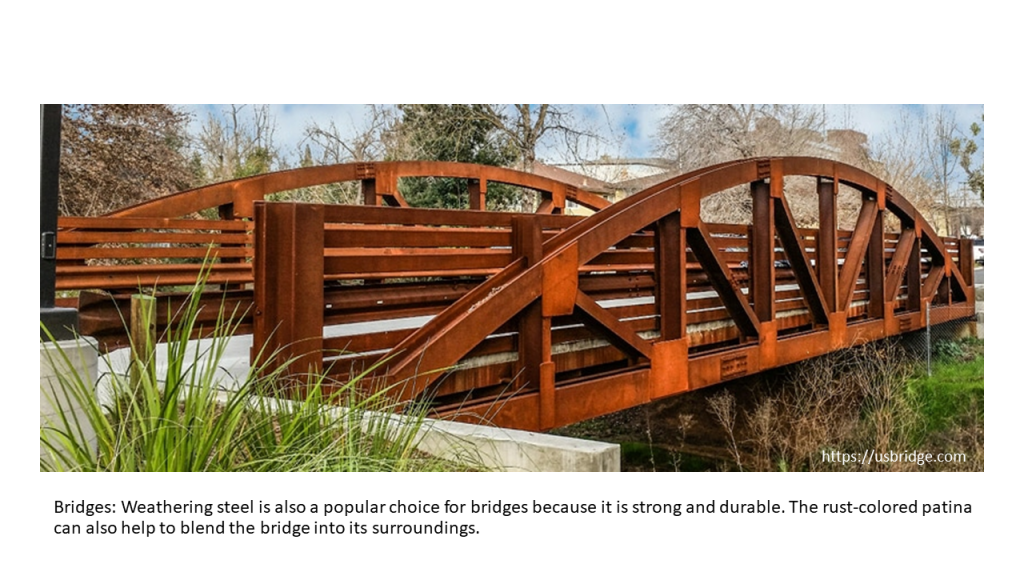

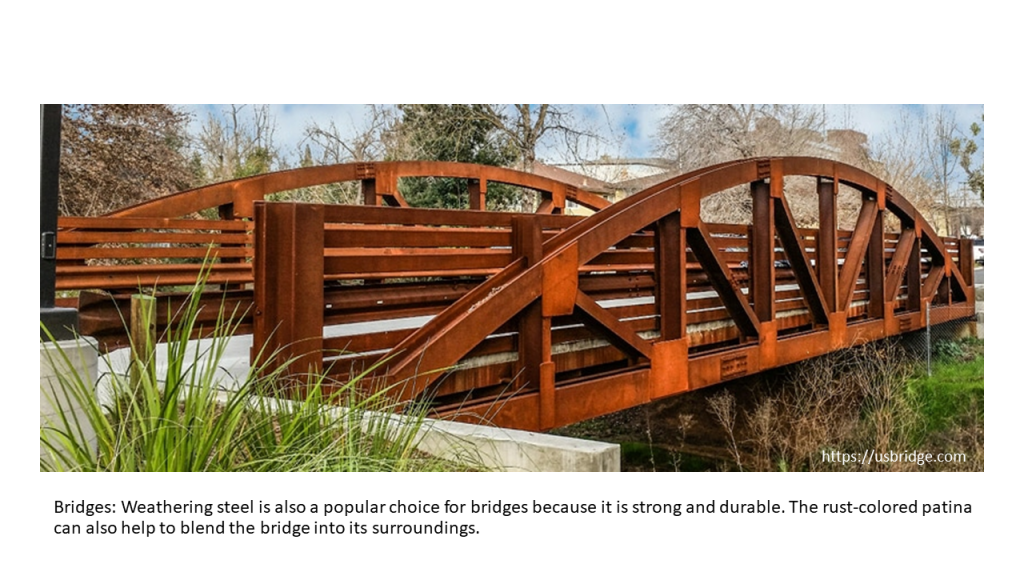

Bridges and Infrastructure: Weathering steel’s durability and strength make it an excellent option for constructing bridges and other infrastructure projects, especially in locations with challenging weather conditions.

Outdoor Sculptures and Art: The distinct rusty appearance of weathering steel makes it a preferred material for creating outdoor sculptures, monuments, and public art installations that blend with their surroundings and evolve gracefully over time.

Landscaping and Garden Structures: Weathering steel is ideal for crafting garden planters, retaining walls, and outdoor furniture due to its ability to withstand exposure to moisture and soil conditions.

Standards for Weathering Steel Production

To ensure the quality and consistency of weathering steel, several international standards govern its production. The most widely recognized standards include:

ASTM A242 and ASTM A588: These American standards define high-strength low-alloy structural steel compositions with improved atmospheric corrosion resistance. They are commonly used in construction and architectural applications.

EN 10025-5: This European standard specifies the requirements for structural steels with improved atmospheric corrosion resistance. It is widely used in Europe and other regions worldwide.

JIS G3114: The Japanese Industrial Standard provides specifications for hot-rolled atmospheric corrosion-resistant steels, widely used in Japan and other Asian countries.

Considerations

When using weathering steel, there are several important considerations to keep in mind to ensure the best performance and longevity of the material. These considerations cover aspects related to design, installation, maintenance, and potential limitations. Here are the key factors to consider:

Exposure and Location: Weathering steel performs best in outdoor environments where it is exposed to natural weathering processes. Consider the specific site conditions, including the level of moisture, humidity, and atmospheric pollutants. In highly corrosive environments or areas with excessive moisture, weathering steel might not be the best choice.

Patina Formation: Understand that the protective rust layer, known as the patina, takes time to develop. The patination process can vary depending on environmental conditions, but it generally takes a few months to several years to fully develop the protective layer.

Initial Staining: During the early stages of patina development, there might be some runoff of rust that could stain adjacent surfaces. Plan for proper drainage and consider protecting nearby surfaces during the initial weathering process.

Welding Considerations: If welding weathering steel is necessary, use the appropriate welding methods and filler materials designed for weathering steel. Improper welding can affect the corrosion resistance of the material in the welded areas.

Design Details: Pay attention to design details, such as avoiding water traps or areas where moisture might accumulate. Proper ventilation and drainage can help prevent localized corrosion.

Maintenance: Weathering steel generally requires minimal maintenance, but periodic inspections are essential to identify and address any issues early on. Regular inspections can help ensure the structure’s integrity and identify areas that may need cleaning or minor repairs.

Avoid Immersion: Weathering steel is not suitable for immersion in water or constant contact with soil, as it can lead to accelerated corrosion. In such cases, consider other corrosion protection methods or coatings.

Protective Coatings: In harsh environments or when weathering steel is used in critical structural applications, additional protective coatings may be considered to supplement the natural patina.

Compatibility with Other Materials: When weathering steel is used alongside other materials (e.g., concrete, stone, glass), ensure that the materials’ interactions do not compromise the integrity of the structure or affect the weathering steel’s protective properties.

Structural Considerations: Weathering steel has different mechanical properties compared to traditional carbon steels. Consider these differences in the design and structural calculations to ensure the structural integrity of the project.

Environmental Impact: Weathering steel is considered an environmentally friendly material due to its self-protecting nature and reduced need for maintenance and coatings. It can contribute to sustainable building practices.

Regular Inspections: Schedule regular inspections to monitor the weathering steel’s condition, especially in structures subject to dynamic loads, like bridges, or in aggressive environments.

Due to its unique properties, weathering steel is commonly used in outdoor sculptures, architectural elements, bridges, building facades, and other outdoor structures where its natural weathered appearance and corrosion resistance are desired. However, it may not be suitable for certain applications in highly corrosive or marine environments where other types of stainless or corrosion-resistant steels are more appropri

สำหรับช่องทางการประชาสัมพันธ์กิจกรรมต่าง ๆ และข้อมูลข่าวสาร ความรู้ ในรูปแบบอื่น ๆ ที่เกี่ยวข้องกับ เหล็กเพื่องานก่อสร้าง ของทางบริษัทฯ ยังมี Facebook Page และ Youtube Channel และ Line Officail Account ชื่อ “WeLoveSteelConstruction” นอกจากนี้ทาง บริษัทฯ ยังมีงานสัมมนาประจำปีที่มีเนื้อหาการบรรยายดี ๆ เกี่ยวข้องกับงานก่อสร้างด้วยเหล็ก รายละเอียดสามารถคลิกตามลิ้งค์ข้างล่างได้เลยครับ

#WeLoveSteelConstruction_Facebook