Truss Systems for Building Roofs and Bridges: A Comprehensive Overview

Truss Systems for Building Roofs and Bridges: A Comprehensive Overview

Roof Trusses

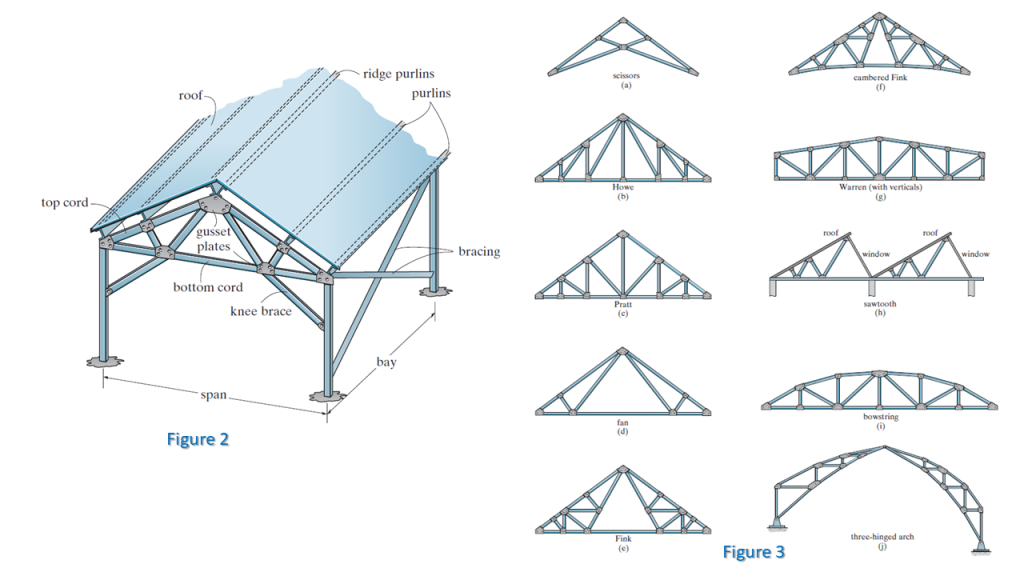

Roof trusses are commonly employed in industrial building frameworks, as depicted in Figure 2. They serve to distribute the roof load to the truss joints via a series of purlins. Typically, roof trusses are supported by wooden, steel, or reinforced concrete columns or masonry walls. This combination of the truss and its supporting columns is known as a “bent.” To ensure rigidity and resistance against horizontal wind forces, knee braces are occasionally implemented at the supporting columns. The space between neighboring bents is referred to as a “bay.” Bays are economically positioned at approximately 4.5 meters for spans of about 18 meters and 6 meters for spans of 30 meters. Diagonal bracing is often used to connect bays together and maintain the structural stability of the building.

The selection of roof trusses depends on factors such as the span, slope, and roofing material. Figure 3 displays some of the commonly used truss types. For shorter spans requiring overhead clearance, the scissors truss (Figure 3a) is suitable. The Howe and Pratt trusses (Figures 3b and 3c) are utilized for roofs with moderate spans, typically ranging from 18 to 30 meters. If larger spans are necessary, the fan truss or Fink truss (Figures 3d and 3e) can be employed. These trusses may be built with a cambered or curved bottom cord, as shown in Figure 3f. In cases where a flat or nearly flat roof is desired, the Howe or Pratt truss can be modified accordingly, as seen in Figures 5a and 5b. Sawtooth trusses (Figure 3h) are commonly used in situations where column spacing is not an issue and uniform lighting is crucial, such as in factories. The bowstring truss (Figure 3i) is sometimes chosen for garages and small airplane hangars, while the arched truss (Figure 3j), despite being relatively expensive, is suitable for high-rise structures and long spans, such as field houses and gymnasiums.

Bridge Trusses

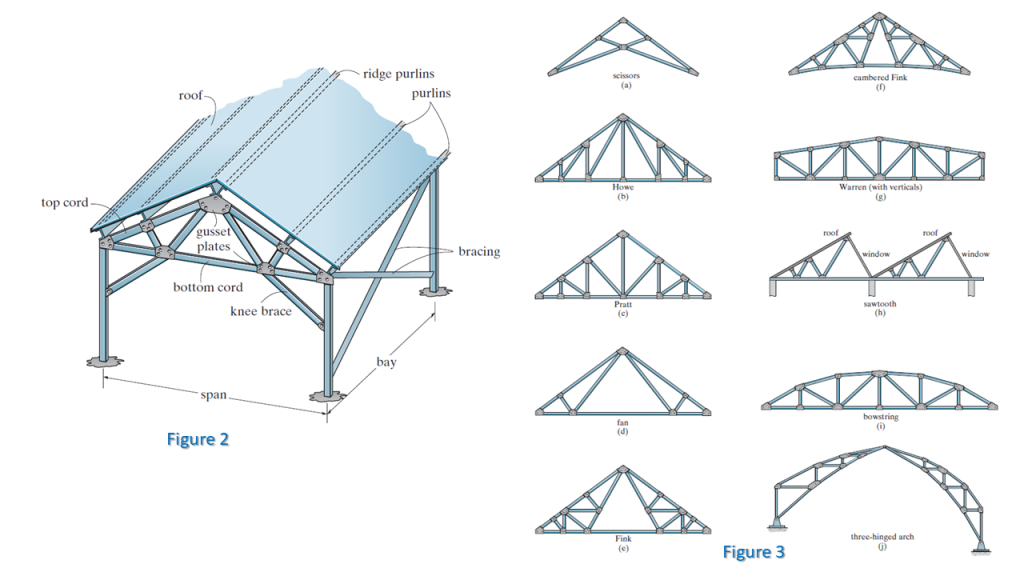

Bridge trusses are key components in the structure of a typical bridge. They are composed of various parts, as depicted in Figure 4. When a load is applied to the bridge deck, it is transferred through stringers and floor beams until it reaches the joints of the two supporting side trusses. To withstand lateral forces caused by wind and uneven vehicle loads, the top and bottom cords of these side trusses are connected by top and bottom lateral bracing. The stability of the truss is further enhanced by the portal and sway bracing. In many long-span trusses, a roller is incorporated at one end to allow for thermal expansion.

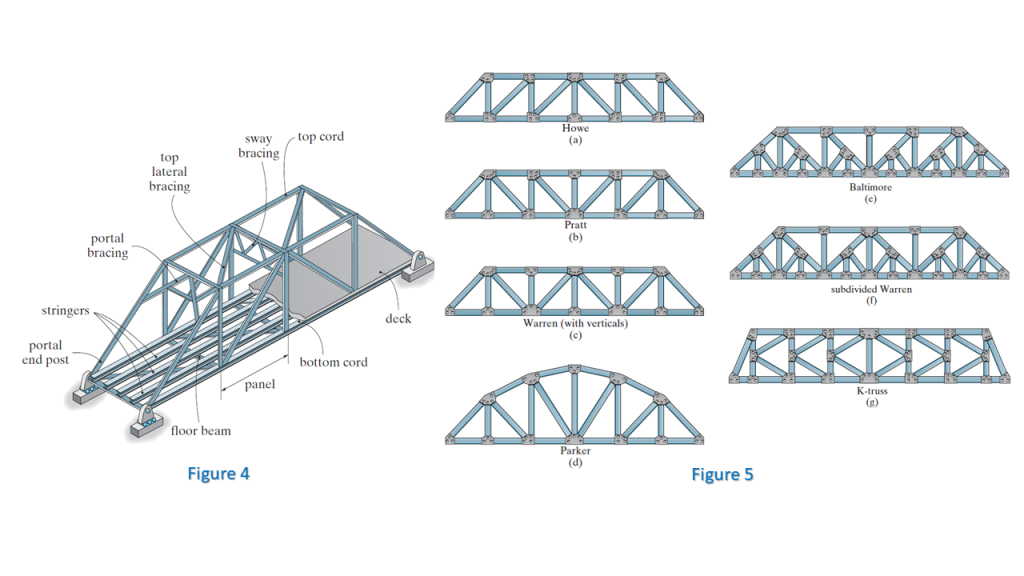

Figure 5 illustrates several common types of bridge trusses used for single spans. The Howe, Pratt, and Warren trusses are typically employed for spans up to 60 meters in length. Among these, the Warren truss with verticals (Figure 5c) is the most widespread. For larger spans, the truss height must be increased to support the greater moment at the center of the span. In such cases, a truss with a polygonal upper cord, like the Parker truss (Figure 5d), is used to achieve some material savings. The Warren truss with verticals can also be constructed in this manner for spans up to 90 meters.

To maintain material efficiency, the diagonals of the truss should have a slope between 45° and 60° relative to the horizontal, particularly for spans exceeding 90 meters. In such instances, the truss depth must be increased, requiring longer panels. However, to control the weight of the truss within acceptable limits, subdivided trusses have been developed, where the diagonals are braced. Examples of these include the Baltimore and subdivided Warren trusses (Figures 5e and 5f). Additionally, the K-truss (Figure 5g) can be used as an alternative to a subdivided truss, serving the same purpose. These design variations optimize the use of materials and ensure the stability and functionality of the bridge truss.

Any questions? Leave comments below, we’ll try our best providing answers for you guys

#WeLoveSteelConstruction

สำหรับช่องทางการประชาสัมพันธ์กิจกรรมต่าง ๆ และข้อมูลข่าวสาร ความรู้ ในรูปแบบอื่น ๆ ที่เกี่ยวข้องกับ เหล็กเพื่องานก่อสร้าง ของทางบริษัทฯ ยังมี Facebook Page และ Youtube Channel และ Line Officail Account ชื่อ “WeLoveSteelConstruction” นอกจากนี้ทาง บริษัทฯ ยังมีงานสัมมนาประจำปีที่มีเนื้อหาการบรรยายดี ๆ เกี่ยวข้องกับงานก่อสร้างด้วยเหล็ก รายละเอียดสามารถคลิกตามลิ้งค์ข้างล่างได้เลยครับ

#WeLoveSteelConstruction_Facebook