Steel Grades and Sections in Construction: A Comprehensive Guide for Architects

Steel Grades: Steel grades determine the mechanical properties and chemical composition of the material. Here are some commonly used grades and their applications:

- Mild Steel (Grade 250 or ASTM A36): Mild steel, with its low carbon content, offers high ductility and is suitable for general construction purposes where high strength is not required.

- High-Strength Low-Alloy Steel (HSLA) (Grade 350 or ASTM A572): HSLA steel contains small alloying elements that enhance its strength while maintaining good weldability. It is commonly used in structures that require higher strength, such as bridges, buildings, and heavy-duty machinery.

- Carbon Steel (Grade 400 or ASTM A588): Carbon steel, with its higher carbon content, provides increased strength and hardness. It is often used in applications that require resistance to atmospheric corrosion, making it ideal for outdoor structures, bridges, and railings.

- Stainless Steel (Grade 316): Stainless steel, an alloy containing chromium and nickel, offers excellent corrosion resistance. It finds applications in architectural elements like facades, handrails, and decorative structures.

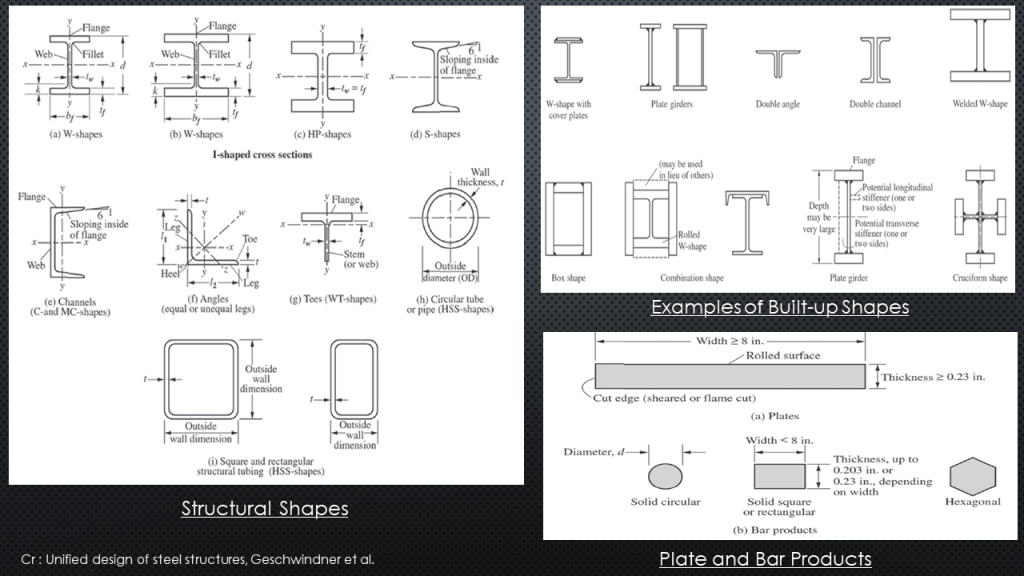

Steel Sections: Steel sections come in various shapes, each with its own unique properties and applications:

- I-Beams (Universal Beams – UB, and Universal Columns – UC): I-beams, with their “I” or “H” shape, offer a high strength-to-weight ratio. They are suitable for beams and columns in buildings and bridges, carrying both bending and axial loads.

- Hollow Structural Sections (HSS): HSS are steel tubes with hollow cross-sections, available in square, rectangular, and circular shapes. They provide structural stability and are commonly used for columns, trusses, and mechanical applications.

- Angle Sections: Angle sections, with their L-shaped cross-sections, find applications in bracing, supporting structures, and as connections in steel frames.

- Channel Sections: Channel sections, with a “C” shape, serve as secondary structural members for purlins, girts, and support systems.

- T-Sections: T-sections, with their T-shaped cross-sections, are commonly used as lintels, load-bearing members, and for reinforcing structures.

- Flat Sections: Flat sections, with rectangular cross-sections, are used in applications such as base plates, brackets, and as stiffeners in steel structures.

- Bar Sections: Bar sections are long, straight steel bars available in various diameters. They are commonly used in reinforcement applications, such as reinforcing concrete structures, providing tensile strength.

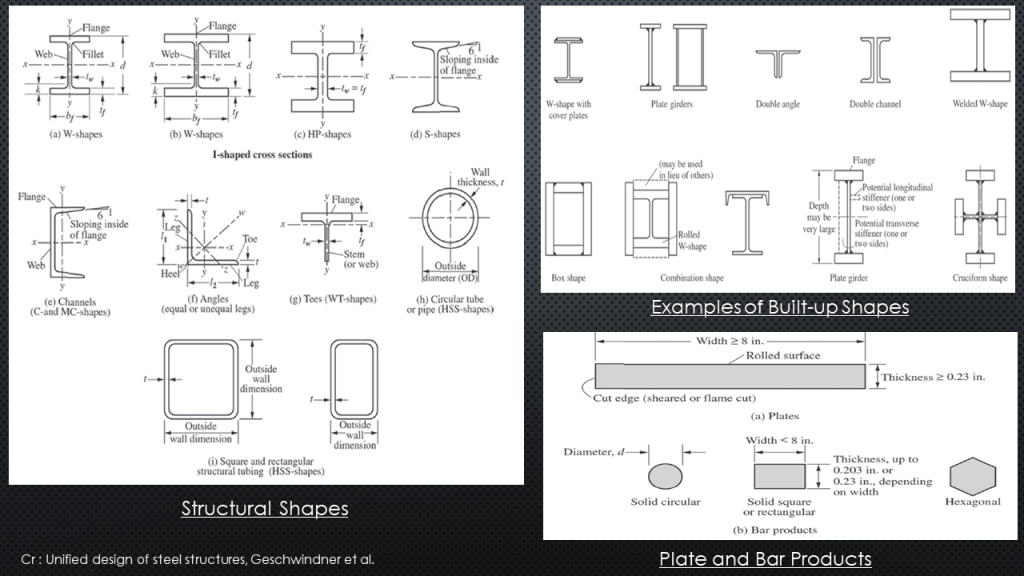

- Built-Up Sections: Built-up sections are created by welding or bolting together multiple steel plates or sections to form a composite section. This process allows for customized shapes and increased strength, making them suitable for specialized applications, such as crane girders and heavy-duty beams.

Note: When using steel grades and sections in construction projects, it is essential to consult with experts, such as structural engineers and material suppliers, to ensure compliance with relevant codes, standards, and safety guidelines.

References:

- American Institute of Steel Construction (AISC)

- American Society for Testing and Materials (ASTM)

- Australian Steel Institute (ASI)

สำหรับช่องทางการประชาสัมพันธ์กิจกรรมต่าง ๆ และข้อมูลข่าวสาร ความรู้ ในรูปแบบอื่น ๆ ที่เกี่ยวข้องกับ เหล็กเพื่องานก่อสร้าง ของทางบริษัทฯ ยังมี Facebook Page และ Youtube Channel และ Line Officail Account ชื่อ “WeLoveSteelConstruction” นอกจากนี้ทาง บริษัทฯ ยังมีงานสัมมนาประจำปีที่มีเนื้อหาการบรรยายดี ๆ เกี่ยวข้องกับงานก่อสร้างด้วยเหล็ก รายละเอียดสามารถคลิกตามลิ้งค์ข้างล่างได้เลยครับ

#WeLoveSteelConstruction_Facebook